مسكن

>

Production capacity of double-toothed roller crusher Calculation

مسكن

>

Production capacity of double-toothed roller crusher Calculation

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Production capacity of double-toothed roller crusher Calculation

Design, Fabrication and Testing of a Double Roll Crusher

Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work. The throughput capacity of the machine was 1.43tonnes/hour. The theoretical efficiency of the double roll crusher when crushing

(PDF) The Influence of the Structure of Double Toothed

2018年11月7日By means of orthogonal experiment, simulation analysis considers the influence factors of the roller spacing, the rotational speed and the pitch angle. The best

Roll Crusher an overview ScienceDirect Topics

The capacity of the rolls can be calculated in terms of the ribbon of material that will pass the space between the rolls. Thus theoretical capacity ( Q, kg h −1) is equal to: (6.7)

Double Roll Crushers McLanahan

Black Diamond Double Roll CrushersHeavy-Duty Double Roll CrushersShalemaster Double Roll Crushers

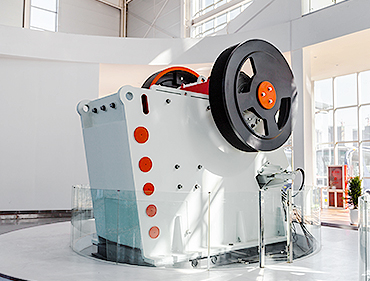

Heavy-Duty Double Roll Crushers are ideal for the primary, secondary and tertiary crushing of limestone, gypsum, ROM coal, etc. where higher compressive strength material is anticipated. Due to the V-belt drive design, a lower horsepower is required compared to other crushers designed for the same applications.

Factors to Consider When Selecting the Proper Roll

2019年11月21日Ratio of reduction. Capacity. Compressive strength. Moisture content. Amount and type of refuse present in the feed. The definition of fines and if minimizing fines generation is beneficial. All of

Crusher Efficiency Calculations Mineral Processing

2014年9月15日The screen area needed under the jaw crusher is 38/1.89 = 20.1 sq ft. For the 1-in. screen below the roll crusher the capacity has no correction factor and the area needed is 32/2.1 = 15.2 sq ft. To handle

Double RollTeethed Roll Crusher Mineral Processing

2016年2月24日The single-roll crusher has a tip speed of 400-450 ft/min while the 6- x 7-ft teethed roll crusher has a normal, no-load, surfaces speed of just under 3500 ft/min. It can be readily appreciated that this

Roll crushers SlideShare

2015年4月24日4. ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone after the output of a quarry has been subjected to one or more stages of prior crushing. Roll crushers

Toothed/Double Roll Crusher Fote Machinery(FTM)

In 2017, Fote double toothed roll crushers were introduced to a Germany mining plant to be used in a pebble crushing line. This pebble production line has a capacity of 100TPH, input size of 50-200mm and output size

Introduction of Toothed Roll Crusher Luoyang Dahua

2022年4月15日On April 15, 2022. Home News Introduction of Toothed Roll Crusher. Toothed roll crusher has a single or multiple motor that drive the belt wheels on the both

PAPER OPEN ACCESS

infrastructure industries are growing in production scale, these industries generally use a large volume of raw materials. In order to study the particle size distribution of the double toothed roller crusher, it is necessary to study the different crushing effect and the stability of the double toothed roller crusher under different conditions.

Dynamics in double roll crushers ScienceDirect

2017年4月1日By taking the double toothed roller crusher as case study, the optimization results show that proposed method can significantly improve the calculation efficiency, and compared with the traditional design, the volume increases by 36.96%, and the failure rate of the planetary gear decreases by 17.05%.

Design, Fabrication and Testing of a Double Roll Crusher

Design and production of an indigenous roll crusher from locally available materials for low hardness rocks was carried out in this work. The throughput capacity of the machine was 1.43tonnes/hour. The theoretical efficiency of the double roll crusher when crushing limestone was 60% while that of kaolin was 80%.

Factors to Consider When Selecting the Proper Roll

2019年11月21日It is good practice to size the width of the rolls to 1-1/2 to 2 times the size of the largest feed lump even though the capacity requirement of the application may be lower than what the crusher can

Crusher Efficiency Calculations Mineral Processing

2014年9月15日For the 1-in. screen below the roll crusher the capacity has no correction factor and the area needed is 32/2.1 = 15.2 sq ft. To handle the output from a 40 x 24 roll crusher the screen will have to be

(PDF) Reliability optimization design of bevel gear ResearchGate

2018年11月7日Finally, DEM of double-toothed roll crusher is established and the above calculation program is applied for analysis. 2. Calculation of Reliability of Gear Transmission System According to...

Toothed/Double Roll Crusher Fote Machinery(FTM)

And this Fote toothed roller crusher has a high crushing ratio as well as a low consumption. Capacity: 25-50TPH Discharge Size: 15mm, 25mm, 30mm Two-Week Delivery and One-Year Warranty Discount Price Latest

Toothed Roll Crusher For Coal Preparation Plant

Toothed roll crusher is widely used in coal, metallurgy, mining, chemical industry, building materials, and other industries, and it is more suitable to crush coal in large coal preparation plant and process waste. Toothed

Double Toothed Roller Coal Crusher Of Adjustable Output Size

2013年4月15日coalfeederbreaker/This kind of coal crushers are mainly used in large type of opencast coal mine, processing capacity can reach from 100-5000t...

Double toothed roll crusher Henan Deya Machinery Co., Ltd.

2022年8月1日According to the original design requirements of the 2PGC-1370A double-toothed roller crusher, the proportion of large ore with a particle size of more than 800 mm in the supplied raw ore shall not exceed 8%, and the actual production process varies greatly, sometimes exceeding 12%.

Toothed roller crusher All industrial manufacturers

Capacity: 40 kg/h 900 kg/h Operation The SFH crushers are equipped of removable hardened teeth and knifes arranged on one or double-shaft. The assembly is drive by an angular and double global motor reducer for decrease the speed and increase impact crusher toothed roller mobile primary Sequence: Drum crusher :

Reliable Toothed Roll Crusher Fote Machinery

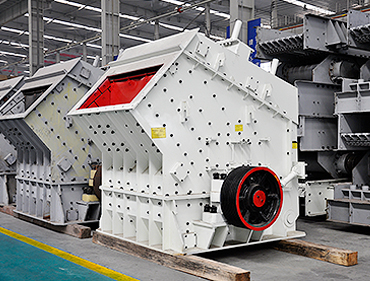

Double toothed roll crusher is suitable for crushing various types of ores, used as secondary or tertiary crushing machinery. It is widely used in construction, metallurgy, building materials, water conservancy, electricity, refractory, and other industrial sectors. 1. Crushing various rocks

Introduction of Toothed Roll Crusher Luoyang Dahua

2022年4月15日Toothed roll crusher has large capacity, high production efficiency and low noise, especially for river pebbles with great crushing effect. Luoyang Dahua is a large toothed roll crusher manufacturer, for the majority of users to provide excellent quality crusher with affordable price.

Optimization of particle size distribution in circulating fluidized

2019年6月15日Next, the two-toothed roll crusher was optimized based on the framework proposed by the Whiten model. The reasonable rolls gap and teeth length should be 75 mm and 23 mm, respectively. Further, a physical model of a two-toothed roll crusher was established to obtain the optimized roll diameter; it was later found to be >660 mm.

PAPER OPEN ACCESS

infrastructure industries are growing in production scale, these industries generally use a large volume of raw materials. In order to study the particle size distribution of the double toothed roller crusher, it is necessary to study the different crushing effect and the stability of the double toothed roller crusher under different conditions.

Dynamics in double roll crushers ScienceDirect

2017年4月1日By taking the double toothed roller crusher as case study, the optimization results show that proposed method can significantly improve the calculation efficiency, and compared with the traditional design, the volume increases by 36.96%, and the failure rate of the planetary gear decreases by 17.05%.

Random Discrete Pulse Load Characteristics of Double Toothed Roll Crusher

2017年12月1日Firstly, the random discrete characteristics of material particles based on production capacity is discussed, the recursive formula of particle bulk density and expression of interval particle

Crusher Efficiency Calculations Mineral Processing

2014年9月15日The screen area needed under the jaw crusher is 38/1.89 = 20.1 sq ft. For the 1-in. screen below the roll crusher the capacity has no correction factor and the area needed is 32/2.1 = 15.2 sq ft. To handle

(PDF) Reliability optimization design of bevel gear ResearchGate

2018年11月7日Finally, DEM of double-toothed roll crusher is established and the above calculation program is applied for analysis. 2. Calculation of Reliability of Gear Transmission System According to...

Toothed/Double Roll Crusher Fote Machinery(FTM)

And this Fote toothed roller crusher has a high crushing ratio as well as a low consumption. Capacity: 25-50TPH Discharge Size: 15mm, 25mm, 30mm Two-Week Delivery and One-Year Warranty Discount Price Latest

Toothed Roll Crusher SlideShare

One or more than one electro motors drive the belt pulley on both sides of the crusher, and the toothed roll will do the opposite rotation. The Application and Description of Roller Crusher: The Performance

Toothed Roll Crusher For Coal Preparation Plant

Toothed roll crusher is widely used in coal, metallurgy, mining, chemical industry, building materials, and other industries, and it is more suitable to crush coal in large coal preparation plant and process waste. Toothed

Introduction of Toothed Roll Crusher Luoyang Dahua

2022年4月15日Toothed roll crusher has large capacity, high production efficiency and low noise, especially for river pebbles with great crushing effect. Luoyang Dahua is a large toothed roll crusher manufacturer, for the majority of users to provide excellent quality crusher with affordable price.

Double Toothed Roller Coal Crusher Of Adjustable Output Size

2013年4月15日coalfeederbreaker/This kind of coal crushers are mainly used in large type of opencast coal mine, processing capacity can reach from 100-5000t...

Optimization of particle size distribution in circulating fluidized

2019年6月15日Next, the two-toothed roll crusher was optimized based on the framework proposed by the Whiten model. The reasonable rolls gap and teeth length should be 75 mm and 23 mm, respectively. Further, a physical model of a two-toothed roll crusher was established to obtain the optimized roll diameter; it was later found to be >660 mm.

Automatic Double Roll Crusher 知乎 知乎专栏

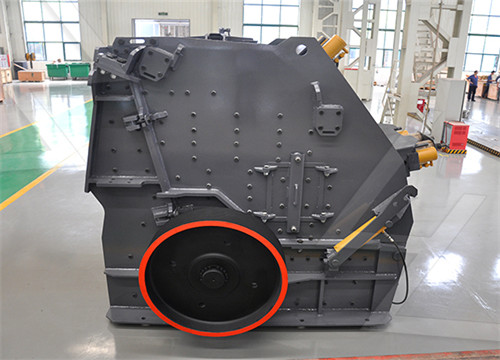

Double roll crusher is mainly used for the crushing of medium or lower-hardness mines and rocks with medium or lower rigidity in mine selection, chemicals, cement and building materials industrial production. Roll crusher machine has a theoretical maximum reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher, the absolute

Roll crusher introduction Henan Deya Machinery Co., Ltd.

2021年8月25日Toothed roll crusher is mainly for splitting and grinding, which is suitable for coarse and medium crushing of brittle and soft ores. The specification of the roll crusher is expressed by the roll diameter D x length L. The parameters of the roller crusher series produced by Henan Deya Machinery Co., Ltd. Roll crusher series technical parameters

Double Roll Crusher Henan Deya Machinery Co., Ltd.

2018年9月12日Toothed roll crusher is mainly for splitting and grinding, which is suitable for coarse and medium crushing of brittle and soft ores. The specification of the roll crusher is expressed by the roll diameter D x length L. The parameters of the roller crusher series produced by Henan Deya Machinery Co., Ltd. Roll crusher series technical parameters